Charcoal burner complex

Charcoal burner complex is designed for woodworking waste recycling: dust, sawdust, wood chips- into high quality charcoal.

Charcoal can be used for coal briquettes production, BBQ, activated carbon, graphite production, as a additive to the soil for plant growth.

Advantages

- small size

- mobility

- firing temperature 900-1200 degrees. This gives high carbon rate (up to 90%)

- charring speed. Temperature allowed us to make high performance-to-size rate machine

- complex runs on its own pyrolysis gas and don’t requires to be heated up while working. Gas composition can be found in attached file below. Excess gas can be used for power generation, heating, etc.

- machine has two regenerative heat sources. The first one is used to power up external consumers (temperature can be from 90 to 200 degrees and is set up by operator). Energy amount is about 400 kwt/h. The second one is used for raw material predrying

- performance is 200kg coal chips per hour, or 4.8 tons per day

- average payback period is 1 year. Service life is at least five years

- optional remote monitoring and control

All thermally loaded components are made of AISI 321 stainless steel.

Kit

- raw material hopper(6 м3)

- intermediate hopper supply screw

- dryer supply screw

- dryer

- reactor

- output screw-cooler

- intermediate coal screw

- coal reception hopper (4 m3)

Gallery

Raw materials

Machine can work with many raw material types.

Here are some of them:

- sawdust

- wood chips

- shavings

- cereals husks

- nut shell

- straw

- reed

- cane

- and much more

More detailed information can be obtained by phone or email

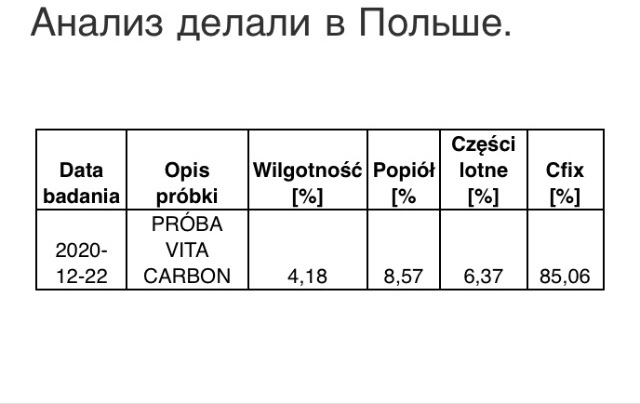

If you have raw material and want to know if it can be used in production, send it to us. We will make charcoal and then send you analysis and material output tablr.